Microbe and mold control

Features/Air/Feature 06

- 01 Air quality standards

- 02 Smoking ban

- 03 Ventilation effectiveness

- 04 VOC reduction

- 05 Air filtration

- 06 Microbe and mold control

- 07 Construction pollution management

- 08 Healthy entrance

- 09 Cleaning protocol

- 10 Pesticide management

- 11 Fundamental material safety

- 12 Moisture management

- 13 Air flush

- 14 Air infiltration management

- 15 Increased ventilation

- 16 Humidity control

- 17 Direct source ventilation

- 18 Air quality monitoring and feedback

- 19 Operable windows

- 20 Outdoor air systems

- 21 Displacement ventilation

- 22 Pest control

- 23 Advanced air purification

- 24 Combustion minimization

- 25 Toxic material reduction

- 26 Enhanced material safety

- 27 Antimicrobial activity for surfaces

- 28 Cleanable environment

- 29 Cleaning equipment

- P9 Advanced cleaning

Microbe and mold control

Intent:

To reduce mold and bacteria growth within buildings, particularly from water damage or condensation on cooling coils.

BACKGROUND

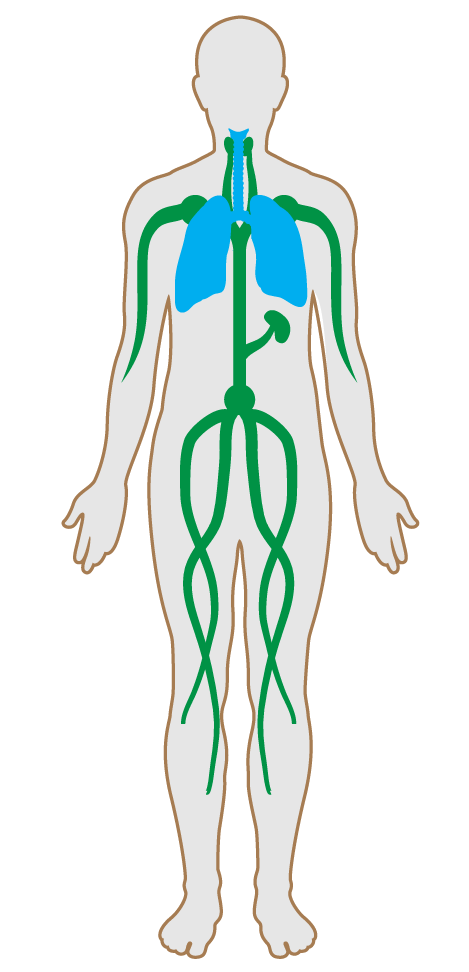

Mold often grows on cooling coils in HVAC systems due to moisture condensation and can be introduced into the building’s indoor air. It can also occur on or within wall assemblies due to water damage or improper detailing in humid locations, for example kitchens and bathrooms. Mold spores can trigger asthma, headaches, allergies and other respiratory system disorders.

In buildings that rely on a mechanical system for cooling, one of the following requirements is met:

a.

Ultraviolet lamps (using a wavelength of 254 nm so as not to generate ozone) are employed on the cooling coils and drain pans of the mechanical system supplies. Irradiance reaching the cooling coil and drain pan, including the plenum corners, is modeled.

b.9

Building policy states that all cooling coils are inspected on a quarterly basis for mold growth and cleaned if necessary. Dated photos demonstrating adherence are provided to the IWBI on an annual basis.