Air filtration

- 1 Air quality standards

- 2 Smoking ban

- 3 Ventilation effectiveness

- 4 VOC reduction

- 5 Air filtration

- 6 Microbe and mold control

- 7 Construction pollution management

- 8 Healthy entrance

- 9 Cleaning protocol

- 10 Pesticide management

- 11 Fundamental material safety

- 12 Moisture management

- 13 Air flush

- 14 Air infiltration management

- 15 Increased ventilation

- 16 Humidity control

- 17 Direct source ventilation

- 18 Air quality monitoring and feedback

- 19 Operable windows

- 20 Outdoor air systems

- 21 Displacement ventilation

- 22 Pest control

- 23 Advanced air purification

- 24 Combustion minimization

- 25 Toxic material reduction

- 26 Enhanced material safety

- 27 Antimicrobial surfaces

- 28 Cleanable environment

- 208 Injury prevention

05. Air filtration

This feature requires proper filtration to achieve reliable air quality performance over time. Carbon filters are designed to absorb volatile pollutants and remove the largest particles, while media filters are meant to address smaller particles. This feature is especially important when outdoor air quality routinely fails the pollutant concentrations outlined in the WELL Air Quality Standards feature.

Part 1: Filter Accommodation

The following is in place in ventilation assemblies in the main air ducts for recirculated air (if recirculated air is used):

a. Rack space to accommodate future carbon filters.

Part 1: Cooling Coil Mold Reduction

In buildings that rely on a mechanical system for cooling, the following is used to suppress mold growth:

a. Ultraviolet lamps are employed on the cooling coils and drain pans of the mechanical system supplies. Irradiance reaching the cooling coil and drain pan, including the plenum corners, is modeled.

b.9 Lamps produce ultraviolet radiation at a wavelength of 254 nm so as not to generate ozone.

c. Lamps have ballasts housed in a NEMA-rated enclosure.

Part 3: Air Filtration Maintenance

To verify that the filtration system continues to operate as designed, projects must annually provide IWBI with:

a. Records of air filtration maintenance, including evidence that filters have been properly maintained as per the manufacturer's recommendations.

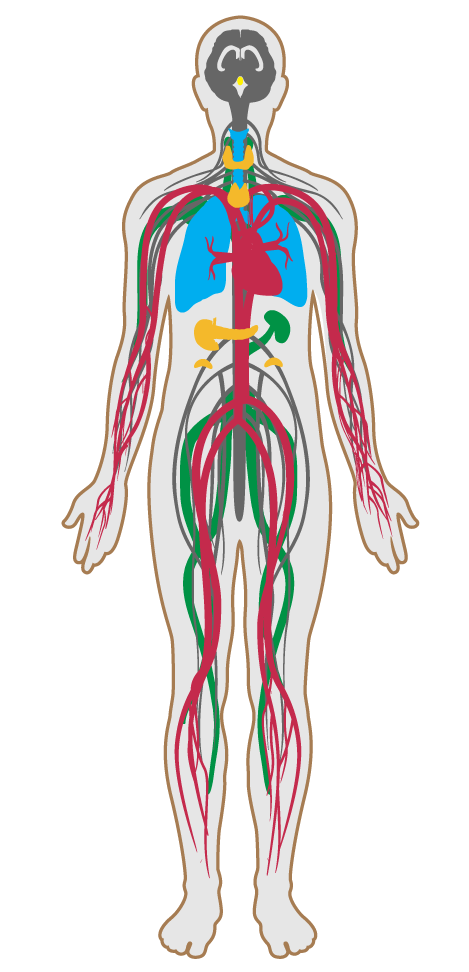

Respiratory

Nervous

Integumentary

Lymphatic

Endocrine

Cardiovascular

Immune

Applicability Matrix

| Core & Shell | Tenant Improvement | New Construction | |

|---|---|---|---|

| Part 1: Filter Accommodation | P | P | P |

| Part 1: Cooling Coil Mold Reduction | P | P | P |

| Part 3: Air Filtration Maintenance | P | P | P |

| Commercial Kitchen | Schools | Multifamily Residential | Restaurant | Retail | |

|---|---|---|---|---|---|

| Part 1: Filter Accommodation | P | P | P | P | P |

| Part 1: Cooling Coil Mold Reduction | P | P | P | P | P |

| Part 3: Air Filtration Maintenance | P | P | P | P | P |

Verification Methods Matrix

| Letters of Assurance | Annotated Documents | On-Site Checks | |

|---|---|---|---|

|

PART 1 (Design) Filter Accommodation |

MEP | Spot Check | |

|

PART 1 (Design) Cooling Coil Mold Reduction |

MEP | Spot Check | |

|

PART 3 (Design) Air Filtration Maintenance |

Operations Schedule |